For information about tile installation, be sure to check out our tile installation tutorials and explore the products, tools and supplies available at Tile Outlets of America for your tile installation project.

Before getting started with your installation, be sure to read Managing Lippage: Why Offsets Matter When Installing Tile so you obtain the offset information you need to properly install your project.

>> See Create a Lippage-free Tile Installation with the Tuscan Leveling System

>> See Learn How to Use the Tuscan Leveling System When Installing Tile

>> See How To Install Tile Correctly and Get Proper Mortar Coverage

>> See How to Manage Moisture in Tile Showers: Schluter Training Session

>> See Perspective on Tile Installation Underlayment from NAC Products Expert, Steve Price

>> Discover NAC Products

>> See GoBoard Lightweight Backerboard and Point Drain Shower Kits

As you go through these FAQs, if you don't find the question - and answer - you're looking for, please contact us!

Porcelain goes through an added process, grinding the clay to make it very fine. When the clay is compressed, it becomes very dense and has very little moisture absorption making it ideal for outdoors.

>> See How Solid Is Your Porcelain vs. Ceramic Tile Knowledge?

In a word, no. Stones that are mud set can be butted. Tiles, because they are fired, will have some size variation depending upon the amount of moisture in the clay at the time of firing. 3/16” grout joint is the smallest we would recommend.

Tiles that are truly rectified can be set closer, however some of the larger tiles will naturally have a slight warp. Rectified tiles are tiles that have been cut after firing to insure uniformity in size.

What determines whether you use sanded or non-sanded is dependent on the size of the grout space. 1/8” or larger use must use sanded grout. Under a 1/8”, usually 1/16 or smaller, you have to use non-sanded in order for the grout to properly pack into the joint. Non-sanded grout is also recommended for installation of glass, metals, or other materials that can easily scratch.

>> See How To Apply Crystal Glass Grout? Jean Snell from The Tile Doctor Demonstrates

>> See Grouting Glass Tile: An Interview With Jean Snell Of The Tile Doctor

Trowel size is dependent on the size of the tile.

- Up to a 14” tile, a ¼ by ¼ square notch is recommended.

- Above 14” but smaller than a 20” a ½ by ½ square notch is recommended.

- About 20”, a ¾” by ¾” is the trowel of choice.

Wall tile set with mastic is usually set with a 3/16” v-notch trowel.

>> See Trowels, Floats and Tiling Tools for more information about the trowels and other tiling tools available at Tile Outlets of America.

Only when setting stone. Stones are porous and the color of the mortar will influence the tile. Black or green stones should use gray mortar. All others should use white. When installing tile, some installers prefer white mortar when they are going to use a light colored grout.

Mastic is meant mainly for wall tile. The rule of thumb is to mortar the floors and mastic the wall. Mortar can be used to set wall tile; however, it is not very sticky and holding the tiles in place until they dry can be challenging unless you use a light weight flexible thinset.

Going over any other surface than virgin concrete you should use a multipurpose mortar ("pro" or "premium" flexible thinset). If you are setting a single fired tile or porcelain you should use a multipurpose as well.

Stones set on the floor require “mud-setting”. There are different methods to doing a “mud-set”. The most common is to use a ¾” square notch to trowel the floor, then trowel the back of the stone or butter the back with mortar.

Using a multi-purpose mortar, tile can be bonded to vinyl flooring. Two things to be careful of:

1. Is the vinyl coming loose?

2. Is the vinyl flooring spongy?

If the answer to either of these questions is yes, then going over the vinyl is not recommended. It is always better to adhere the tile directly to the substrate. The multipurpose mortar will bond the tile to the vinyl, but it will not prevent the vinyl from coming loose. In essence you are putting good money over bad. Direct bonding to the substrate is best.

Crack suppression is used to minimize the tile’s exposure to stress from the slab.

Before setting the tile, you should walk the slab and look for cracks. If you only have a few cracks then you can use a crack suppression kit. If the slab is new or under three years old then crack suppression should be used on the entire area to be tiled.

>> See Why Underlayment Matters to a Tile Installation Project

- PEI I – tile has lowest wear resistance and is suitable for wall use only

- PEI II – tile has low wear resistance and is suitable for wall use and for floor areas with light traffic such as residential bathrooms

- PEI III – tile has moderate wear resistance and is suitable for all residential uses and in commercial areas where light to moderate foot traffic is anticipated

- PEI IV – tile has high wear resistance and is suitable for all residential uses and all medium commercial and light industrial uses

- PEI V – tile has highest wear resistance and is suitable for all residential, commercial and industrial uses

>> See How PEI Helps You Select Ceramic or Porcelain Tile for Your Remodel

- High absorption (non-vitreous) tiles absorb more than 7% of their weight and are not suitable for outdoor areas or wet area environments such as showers

- Moderate absorption (semi-vitreous) tiles absorb 3% to 7% of their weight and are not suitable for outdoor areas or wet area environments such as showers

- Low absorption (vitreous) tiles absorb 0.5% to 3% of their weight and are suitable for outdoor areas and wet area environments such as showers

- Lowest absorption (impervious) tiles absorb less than 0.5% of their weight and are suitable for all indoor and outdoor uses

- C.O.F. of 0.60 or greater (wet) – indicates the tile is slip resistant, is suitable for all residential and commercial uses and meets or exceeds general safety and health regulations, ADA and OSHA requirements

- C.O.F. of 0.50 to 0.59 (wet) – indicates the tile is conditionally slip resistant, is suitable for standard residential uses and meets or exceeds general safety and health regulations and OSHA requirements

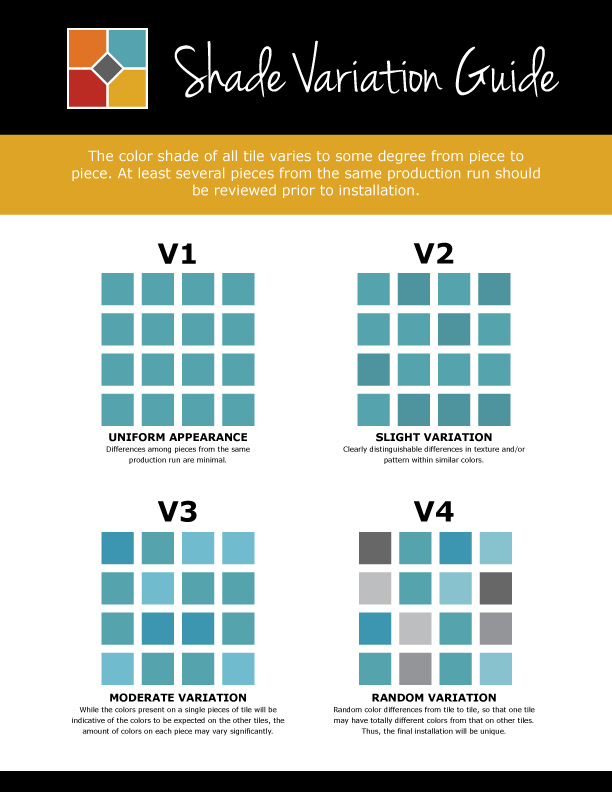

- V1 = UNIFORM APPEARANCE – Differences among pieces from the same production run are minimal.

- V2 = SLIGHT VARIATION – Clearly distinguishable differences in texture and/or pattern with similar colors.

- V3 = MODERATE VARIATION – While the colors present on a single piece of tile will be indicative of the colors to be expected on the other tiles, the amount of colors on each piece will vary significantly.

- V4 = SUBSTANTIAL VARIATION – Random color differences from tile to tile, so that one tile may have totally different colors from that on other tiles. Thus, the final installation will be unique.

>> See How to Deal with Shade Variation in Porcelain and Ceramic Tile?

>> To learn more, see What is Rectified Tile and Why Does It Matter for Your Tile Installation?

>> To learn more, see How Inkjet Technology Has Transformed Ceramic and Porcelain Tile